International architectural design firm Zaha Hadid Architects (ZHA) based in London, UK, is known for creating iconic, transformative, and cultural architecture in harmony with its surroundings. Zaha Hadid’s design atelier, founded in 1979, was an early pioneer and adopter of key necessities of innovation: theoretical guidance, systemic knowledge generation and collaborative design. The Computation and Design research group (co|de) of the company was an effort initiated in 2007, in line with the preceding pioneering efforts of the company. The co|de team endeavours to develop early-design methods that enable a directed search for physically, economically and ergonomically feasible solutions within a vast universe of architectural possibilities enabled by digital design and construction methods.

Tucked away in a remote location in the mountains, designed by ZHA, the Lushan primary school, when complete, will be an educational institute located 160 kilometers North-West of Nanchang, the capital of China’s Jiangxi province. Sitting atop an elevated escarpment above the 50-year flood level on a small pensinsula, the school will be surrounded by mountains, rivers, and lakes, providing a serene environment conducive to outdoor educational and sports activities.

An Extraordinary Achievement for an Extraordinary Learning Environment

The school program is designed to ease the transition between the Foundation Stage, for children of 3 to 6 years of age, and the Primary Stage for children of 6 to 12 years of age. At a planned capacity of 14 pupils each for the 9 classrooms, the total number of students is expected to be approximately 120, serving 12 local villages with a total population of about 1,800 people. Established by Jinggan Yu, President of the College of the Arts in Jiangxi, the school design is defined by his vision to create opportunities for children in his hometown to grow and develop in an inspirational learning environment.

Presented with the challenges of building in this remote location, ZHA elected to source local building materials, leveraged advanced on-site manufacturing techniques, and utilize Altair HyperWorks™ simulation software to drive conceptual design and virtually evaluate structural performance.

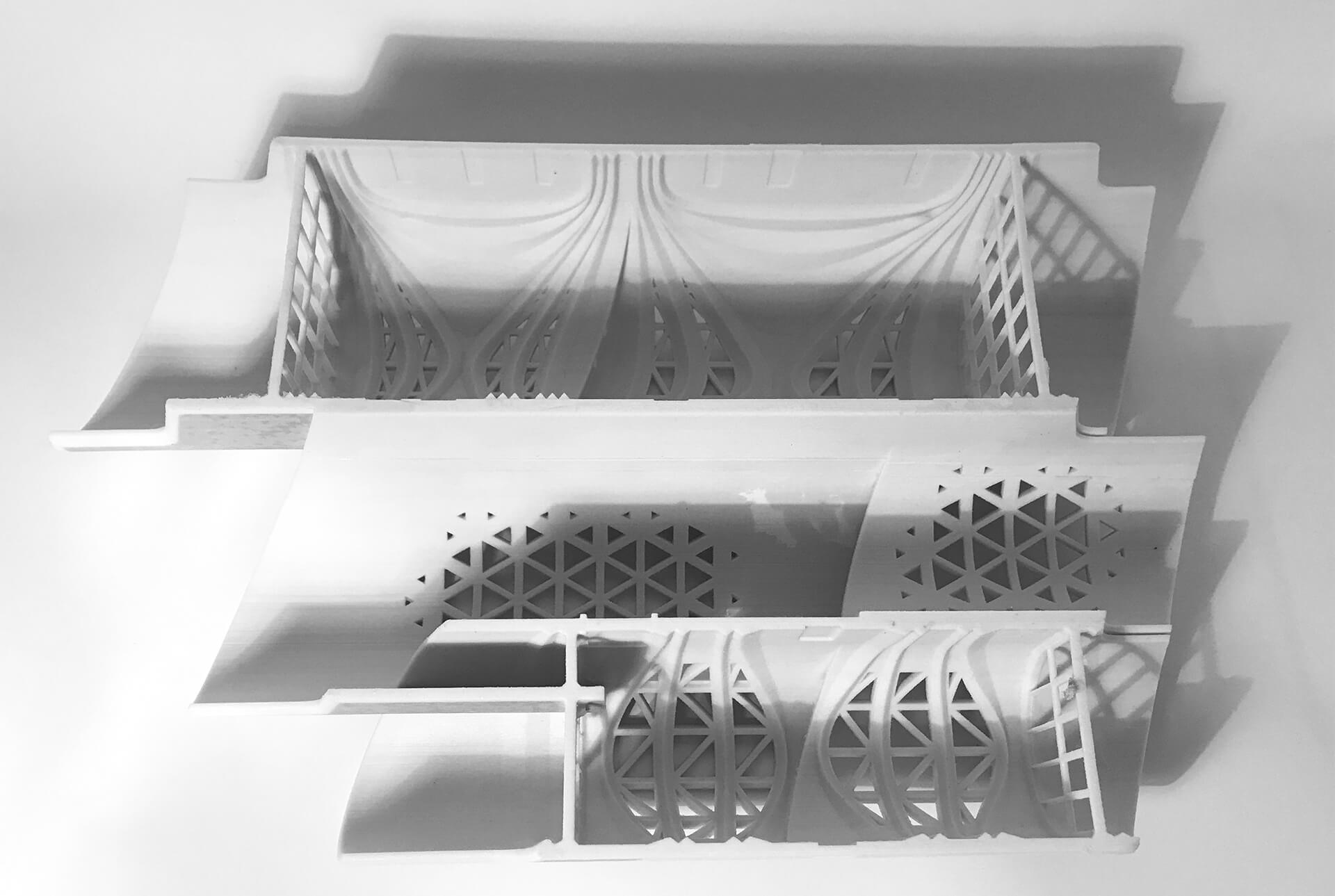

Framing views of the surrounding landscape, the vaulted classrooms are oriented to capture the best natural light conditions. A network of barrel and parabolic vaults stretch and intersect the campus style layout comprising of the school, dormitory, and utility buildings, with a long open courtyard in the center. Cantilevers attenuate the impact of Jiangxi’s sub-tropical climate, protecting the classrooms from the solar gain, while extending the teaching spaces into the landscape to provide a varied and interactive learning environment.

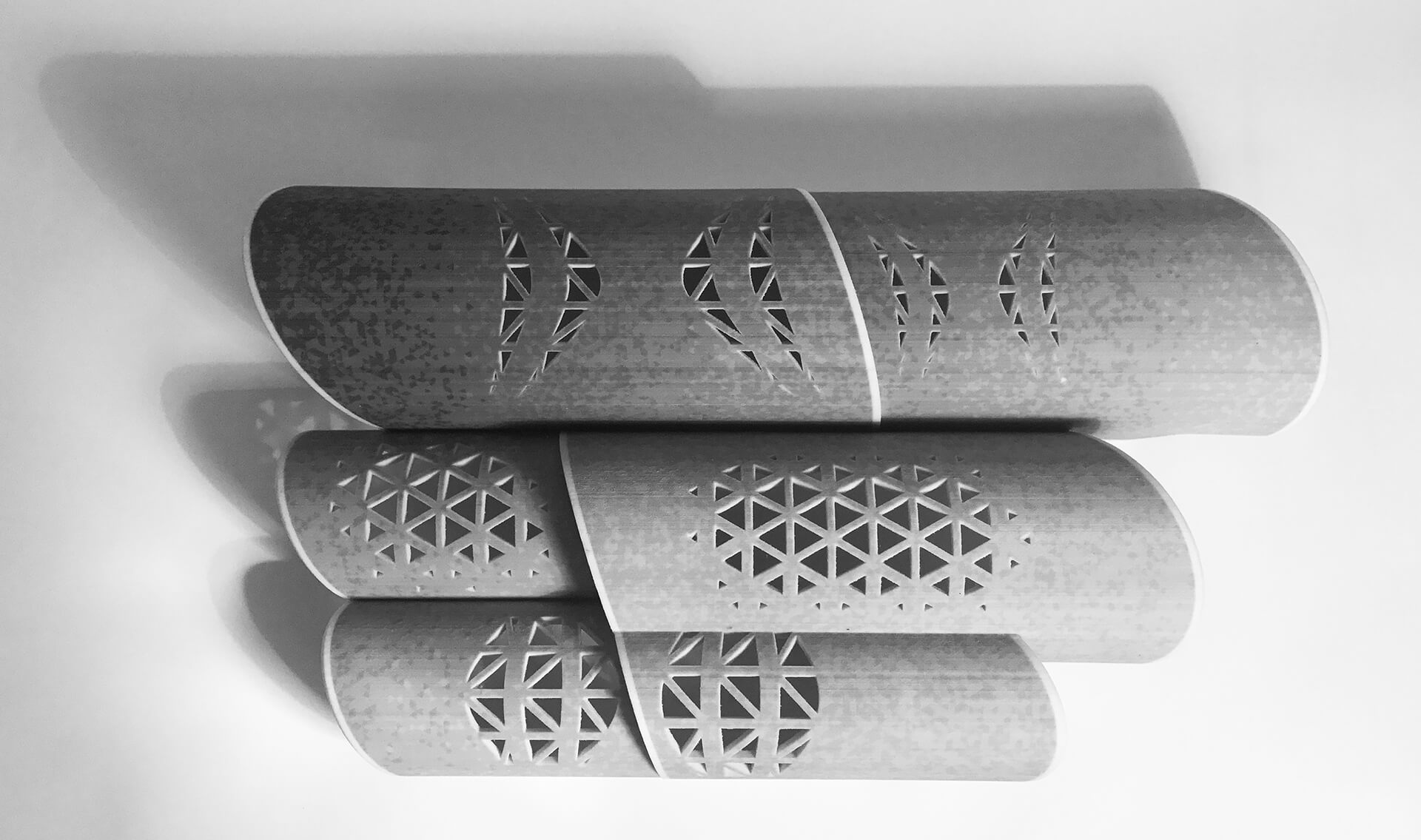

Zaha Hadid proposed building of the school on-site using local building materials and techniques. To minimize construction time and reduce separate building elements to be transported to the location, they suggested combining the local skills of in-situ concrete construction with new advancements in hot-wire cut foam formwork which enable the production of complex concrete structures that can be prepared on-site by industrial robots.

Given the remote location, one of the main advantages of the design is that any type of variation to be performed with the formworks on site would require a very small family of casting elements. As an example, to make a vault, just one mold would basically need to be made for the casting. Demonstration of a social variation within the school was required to facilitate wayfinding within the individual elements. ZHA elected to implement topologies in the structure itself as a way for students to identify locations and navigate the campus.

Bringing in any type of variation was not something that could be done because of the remote formwork requirements, as it would be extremely expensive. The co|de team eliminated the complexity of that formwork-making by opting to use regionally available foam, and by using robotic techniques to cut the pieces on site and assembling them to cast the vaults. Given the planned school’s remote location, this is no ordinary achievement.

Using Altair HyperWorks to Drive Conceptual Design for Accuracy Downstream

Structural possibilities and rib considerations using robotic techniques became the design driver for sculpting the formwork that would then become a series of articulations for each of the vaults. Each of the vaults has a patterning developed from a structural perspective, designed for activities specific to interior and outdoor learning activities.

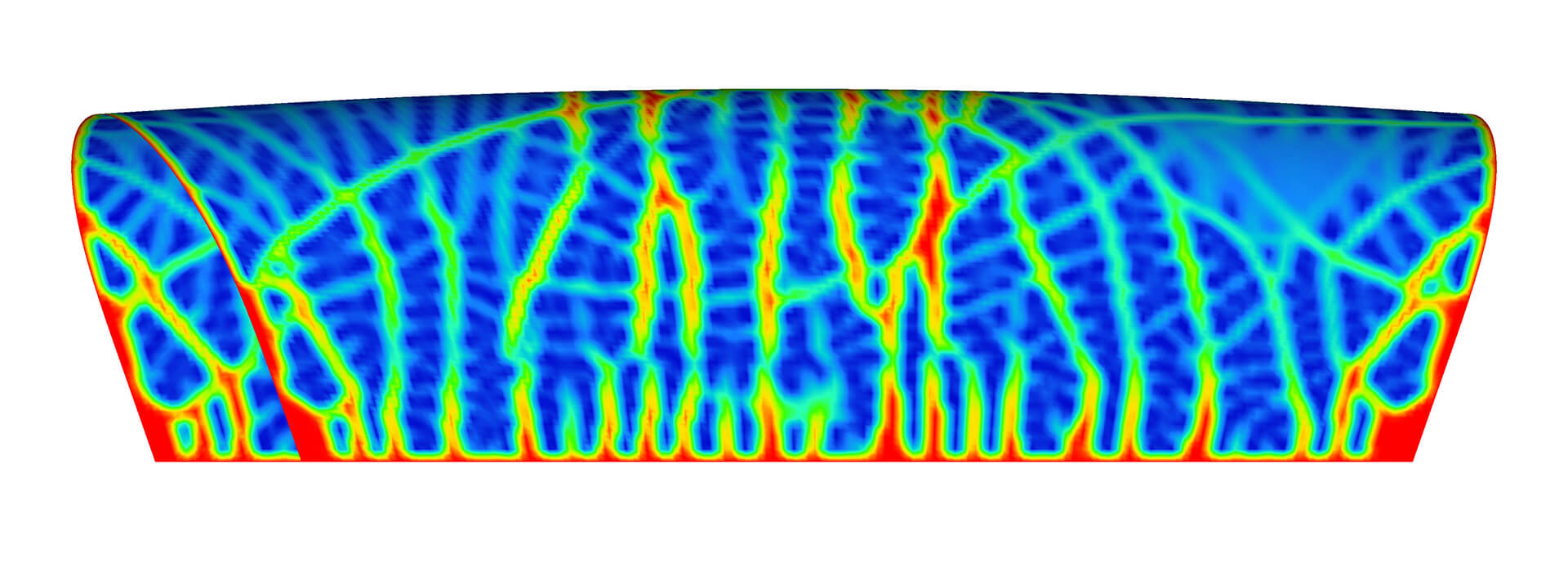

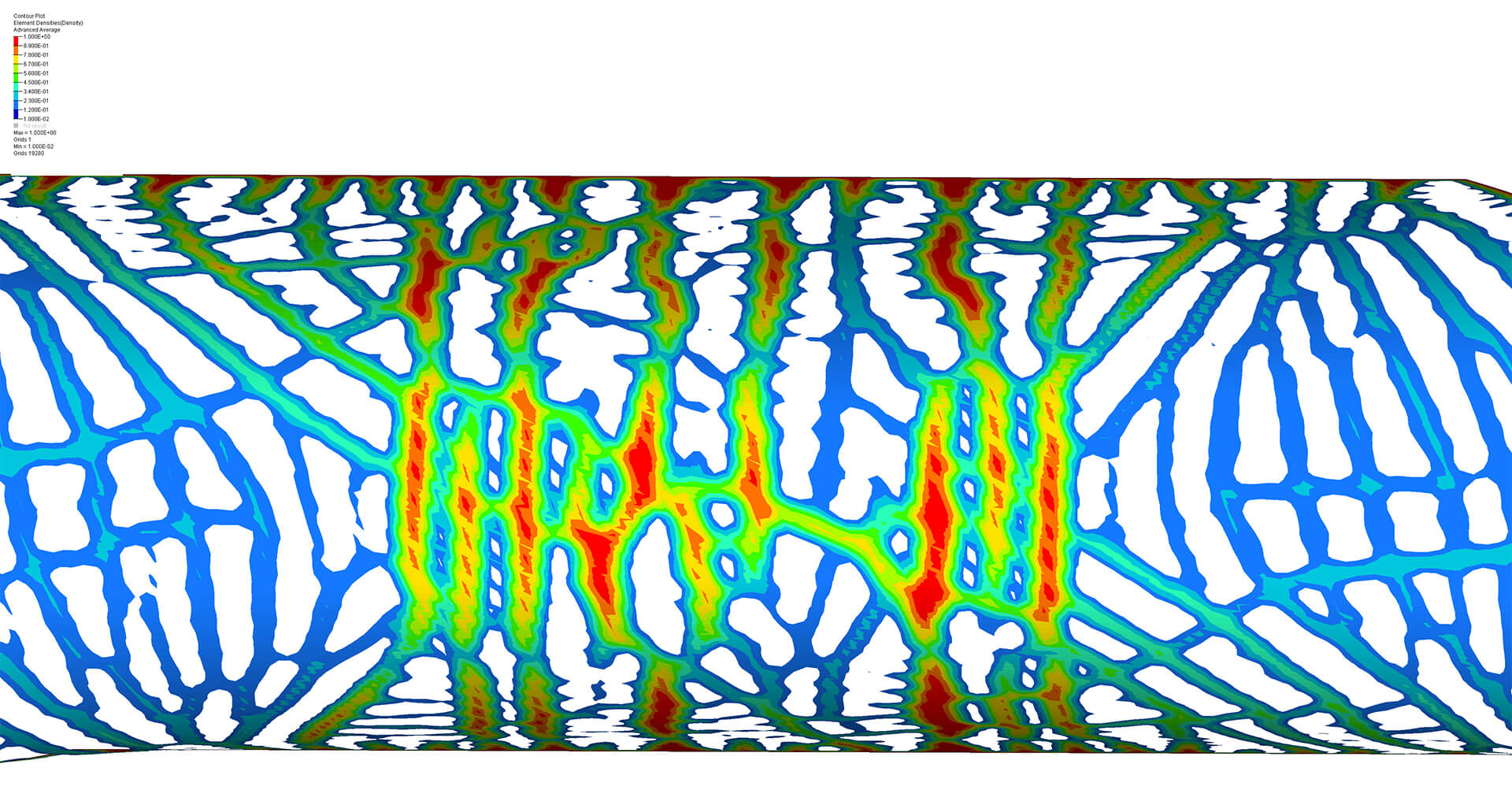

The co|de team began with Altair HyperMesh™, Altair's modeling software part of the HyperWorks simulation suite, to explore early concept design. With the inner part of the vault driving design logic, the main structural ribs or the perforation pattern became a primary focus for them. Ribbing, implementation of ruled surfaces across vaults, and topology related to cantilevers were all considerations for the effect on patterning and evaluation of structural feasibility.

Being highly interested in its intuition, the co|de team used Altair HyperWorks™ as a conceptual tool and a design driver rather than an engineering tool. With a fundamentally different approach, rather than run a single simulation, they opted to perform several in order to explore a range of opportunities for a particular set of topologies. When not possible to overlay a particular constraint, it was possible to overcome that downstream with the software, which is more intuitive to designers in the group. With this approach, the co|de team retained the accuracy of the intuition within the general geometry, while permitting changes downstream that allowed them to exploit each particular design drivers such as the important navigational criterion of the wayfinding experience within the space

Altair OptiStruct™ is used for material reduction, resulting in a lighter, more efficient design, with less rebar required. Material reduction affords intuition for placement of glazing, and the inclusion of perforations for lighting within a vault which is otherwise a significant length.

With a constant interest in how space can be encoded, HyperWorks has been used by the team to facilitate lightweight design, structural feasibility, high-fidelity between design concept and production, and integration with fabrication.

“We all know that there are free tools on the market, with some of these capabilities, but not to the level of rigor and output being as professional, high-resolution or being able to interface with at the level which Altair software allowed us to do. Not all software is the same. They may look like they do the same thing but the Altair software package has been able to do it better,” says Henry Louth, Senior Designer, Zaha Hadid Architects. “We consistently prefer Altair because the color mapping, the output tools, the high-resolution tools, the ability to tweak the constraints much more specifically, and to be able to get output videos – are very relevant to us.”

Through a culmination of design innovation, modern fabrication techniques, and simulation, ZHA is bringing an extraordinary learning environment to the children and families of Lushan – a testament to technology and creative spirit to inspire generations to come.